The Coating Code of PPF: Hydrophilic or Hydrophobic? Here’s the Scoop!

China now has 430 million vehicles on the road. As car ownership grows, drivers aren’t just washing their rides – they’re demanding smarter paint protection. PPF (paint protection film) has shifted from a luxury to a must-have. But with booming demand comes cutthroat competition:

Lower-end market: Slashing prices (race to the bottom!).

High-end market: Battling over tech breakthroughs.

Here’s the truth: Cheap price wars hurt everyone. Copycat products flood the market, and no one wins. The real opportunity? Tech-driven differentiation – like next-gen coatings that outshine rivals.Brands that innovate (like perfecting these coatings) will own the future. The rest? Stuck in the discount bin.

Emphasizing New Coat Technology for Car Wraps to Seize Industry Momentum

As is widely recognized, car wraps derive their scratch-resistant and tear-resistant properties from the TPU substrate. High-quality TPU-based wraps offer superior paint protection and long service life. Equally critical are the self-cleaning, self-healing, and high gloss enhancement functions of car wraps, which stem from the coating on the TPU substrate. The quality of the coating not only determines the effectiveness of self-cleaning but also plays a pivotal role in maintaining the aesthetic appeal of the vehicle. Therefore, when selecting a car wrap, consumers prioritize the self-cleaning performance of the coating to ensure their vehicle's daily appearance.

Discriminating Between Hydrophilic and Hydrophobic: Hydrophobic Coatings Truly Shine in Car Wraps!

While many clear bras (paint protection films) claim to have self-cleaning capabilities, their actual performance often falls short of expectations. Surprisingly, even some detailing shops are unaware that coatings can be categorized into hydrophilic and hydrophobic types. Let’s delve into this distinction.

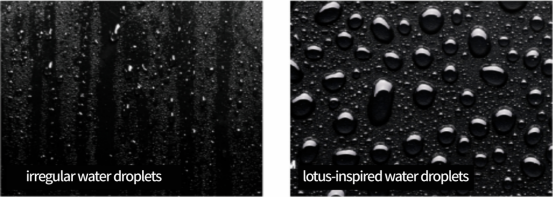

Some vehicle owners have noticed that after rain, as the water evaporates, black or white rain spots may appear on the surface of the wrap, similar to the image below. This phenomenon highlights the critical difference between coating types—hydrophobic coatings excel at repelling water and contaminants, minimizing residue buildup, while hydrophilic coatings may struggle to prevent such unsightly marks. Understanding this distinction is key to choosing a car wrap that delivers both functional performance and lasting visual appeal.

Industry experts note the core issue is weak hydrophobicity in car wrap coatings, causing water droplets to cling and leave marks as they evaporate. Poor coating density can let residues penetrate, making marks permanent and reducing the film's lifespan.

Hydrophilic vs. hydrophobic coatings are defined by water contact angles: <90° hydrophilic, <10° super-hydrophilic; >90° hydrophobic, >150° super-hydrophobic.

In terms of car wrap coatings, theoretically, both enhancing hydrophilicity or hydrophobicity can achieve self-cleaning effects. However, it's important to note that hydrophilic surfaces require a contact angle below 10° for optimal self-cleaning, while hydrophobic surfaces can achieve decent results without extremely high hydrophobicity.

Statistical experiments by companies show that most car wraps on the market use hydrophilic coatings. However, these coatings rarely achieve super-hydrophilicity (contact angle <10°). Most have contact angles between 80°-85°, with the lowest

reaching only 75°

.

(The test images are from the internet.)

Thus, the self-cleaning effect of hydrophilic car wraps on the market is generally unsatisfactory. After applying hydrophilic paint protection films, the vehicle body contacts a larger area of sewage during rain, making stains more likely to adhere to the paint surface and hard to clean.

Professionals note that hydrophilic coatings feature simpler production processes and lower costs than hydrophobic ones. Hydrophobic coatings require adding extra nano hydrophobic and oleophobic materials, with extremely strict process demands—unattainable for most factories. This is why hydrophilic car wraps are more common in the market.

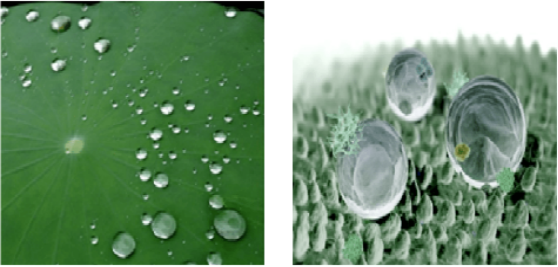

However, when tackling the poor self-cleaning performance of paint protection films, hydrophobic car wraps have distinct advantages. Their hydrophobic coatings work similarly to the lotus leaf effect.

The lotus leaf effect works as follows: after rain, the rough micro-morphology and epidermal wax on the lotus leaf surface prevent water droplets from spreading or sticking. Instead, water forms beads. As the leaf sways gently in the wind, these beads roll off, carrying away dust and dirt along with them.

Under their own gravity, water droplets easily roll off the film surface. As they roll, the droplets also carry away dust and sludge on the film, achieving a self-cleaning effect.

How to distinguish hydrophilic and hydrophobic car wrap coatings? There are two main methods:

1.Use professional instruments to test the contact angle.

2. Make a preliminary judgment based on how water rolls on the film surface.

Generally, a hydrophilic surface forms water droplets that easily adhere. A super-hydrophilic surface shows no distinct droplets—just a wet appearance. A hydrophobic surface also forms droplets, but these flow under gravity, converge, and run off, keeping the surface dry. The super-hydrophobic effect is more pronounced.

Identifying Hydrophobic vs. Hydrophilic Car Wraps

Thus, when pouring water on a car wrap: scattered, hard-to-flow droplets mostly indicate a hydrophilic coating; converging, flowing-away droplets revealing a dry surface suggest a hydrophobic coating. Note that visual judgment is for reference—prioritize reliable manufacturers and professional brands.

(Excerpted from online sources above)

Since 2020, the R&D team of Chelimei has conducted market research and technical development on automotive paint protection films and vehicle color-changing films. They innovatively developed a "coating technology breaking industry boundaries"—the fluorocarbon anti-fouling coating, featuring super hydrophobicity. (As shown in the image below)

As shown in the image above, the paint protection film under Chelimei brand displays water droplets that perfectly mirror those on lotus leaves, vividly demonstrating its robust hydrophobic effect.

As shown in the image above, the color change film under Chelimei brand displays water droplets that perfectly mirror those on lotus leaves, vividly demonstrating its robust hydrophobic effect.

LATEST NEWS

- PPF(paint protection film),What is the pros and cons of the car paint surface? 2025-03-27 13:30:54

- Don’t Fall For Cheap Car Wraps! A High-Quality PPF Or Color-Change Film Should Cost ¥2000-4000! 2025-03-28 16:36:33

- Why Do Top-Quality PPFs & Color Films Love Ashland’s Adhesive? 2025-03-28 16:41:46

- The Coating Code of PPF: Hydrophilic or Hydrophobic? Here’s the Scoop! 2025-03-28 16:47:37

- How To Identify PET vs. PVC Vehicle Wraps? 2025-03-28 16:55:46

- The Difference Between The Paint Protection Films And Color Change Film 2025-03-28 17:01:37

- Does Your Car Need to Be Registered After Applying a Color-Change Film? 2025-03-28 17:05:06

- LED-UV curable fluorocarbon Anti-fouling coating Car Wrap – Worth a Recommendation? 2025-03-28 17:08:08

- What Are The Effects Of Cold Winter Weather On Car Paint? 2025-03-28 17:11:27

- Top-Tier Luxury SUV – Rolls-Royce Cullinan Installed with MOTJ Paint Protection Film 2025-03-28 17:13:35